Product

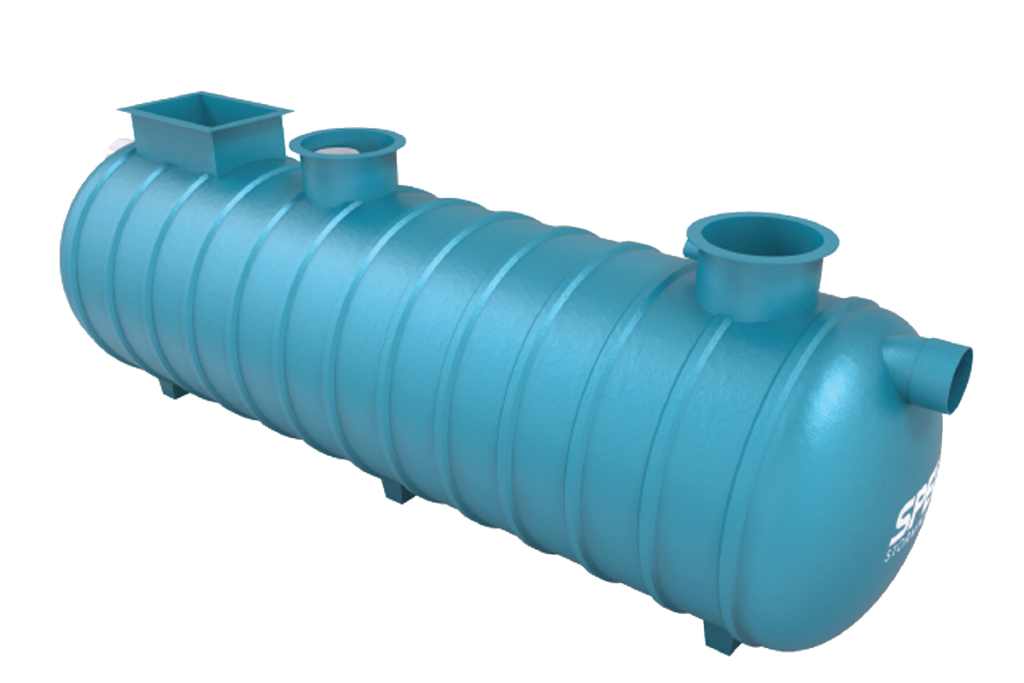

SPEL Puraceptor

SPEL Puraceptor, now known as Spillceptor, is a full retention separator that provides guaranteed hydrocarbon capture and spill containment.

Formerly part of our SPEL Stormwater product range, now available at atlan.com.au.

Applications

- Power Stations

- Substations & Switchyards

- Renewable Energy

- Waste Transfer Depots

- Refuelling Areas

- Service Stations

- Asphalt Plants